Titespot® Angle Heads | How They Work

Titespot® – The Proven Solution

Eliminate secondary operations. Improve accuracy. Reduce tool and set-up costs.

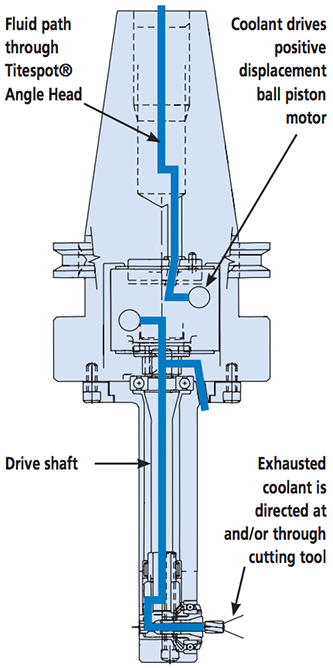

Titespot® angle heads are a proven solution to the old problem of right angle machining in confined areas. They utilize your high pressure coolant system to drive an integral positive displacement ball piston motor. As shown in the illustration, the motor powers a drive shaft , in turn driving the head’s spindle. Exhausted coolant is directed at and through the cutting tool.

Because the Titespot angle head has its own power source (the coolant), your machine’s spindle is free to function as an indexer, allowing multi-position machining with one head and set-up. A simple modification of your M19 spindle orientation on machines with a rigid tapping program lets you index our angle head through a full 360 degrees. Titespot heads load easily from your ATC, and unlike mechanically driven heads, no C-axis or stop block is required. In fact adding a Titespot Angle Head to your tooling package is virtually like adding a C-axis to your machining center.

Because Titespot Angle Heads do not require bearings for support, they clamp rigidly into the spindle, allowing for more compact design with minimum deflection. Titespot Angle Heads can machine in bores as small as 5/8″16mm in diameter and have been manufactured in lengths up to 36 inches914 millimeters.

Angle Heads Product Content

Durable, Versatile & Custom Angle Heads

Titespot® angle heads are manufactured to exacting standards and feature hardened spiral miter gears for efficient power transfer and durability. Our engineering staff can also design heads with custom angles, straight heads, and other special units for your application. To find out more, call toll free 1-877-435-8665.

Titespot® Angle Heads Advantages

- Fully indexable on most CNC Machines

- Machines in cavities down to 5/8″16mm

- Loads from ATC. No stop block required

- Eliminates secondary operations

- Speeds to 13,500 rpm

- Elliptical head provides maximum rigidity in minimum bore

- External or through-the-tool coolant capability

Typical Angle Head Applications

Multi-position exhaust ports drilled radially in the bore of an aluminum overhead door closer (cutaway).

Two rows of bleeder ports drilled radially in the piston bore of a cast iron hydraulic motor housing.

Spiral grease channels milled and drilled in the bore of a bronze bushing.